Do you…

…like to develop a new assay,

…need to optimize an existing one or

…just want to transform your reagent mixture into a freeze-dried version?

Applyo supports you in assay-, formulation- and lyophilization development. With our services you can enhance your development possibilities, expand your capabilities and accelerate your time-to-market. Avoid numerous trial-and-error loops with our systematic approach.

Definition of Product and Material

→

Design or Adaption of Reagent Mixtures

→

Optimization of Reagent Mixes

→

Development of QC Methods

→

Compilation of Documents 21CFR 820 + ISO13485

→

Validation and Verification

→

Support for submissions to regular authorities

1. Definition of product and materials

Your product with its unique characteristics will be analyzed in detail with our experts before the design of the formulation starts. A common understanding of the desired properties is the basis for our streamlined development project.

In this analysis we also discuss boundaries such as production or transport conditions, while taking Regulatory Requirements (e.g. TGS-1 to -8 seriesa and ISTA 2Ab) into account.

Even after extreme and unlikely transport conditions our Applyo RMDx RT-qPCR beads will show optimal performance and shelf-life.

a https://apps.who.int/iris/discover?rpp=10&etal=0&query=tgs&group_by=none&page=1

b ISTA 2A standard defines conditions for transport simulation and is accepted by the FDA for Medical Device Packaging. https://ista.org/test_procedures.php#partial-simulation-section

2. Design or adaptation of formulation

Almost every master mix can be transferred to a freeze-dried version. However, adaptations are recommended or even mandatory to obtain a cost-effective and robust product with high quality. With Applyo’s experience in formulation development we can significantly improve your products performance, shelf-life and overall product costs.

3. Optimization of mixes with respect to shelf-life and robustness, performance, production costs (DFMA)

To achieve the best product performance with minimum optimization loops during product development, we approach projects with well thought development strategies. With our commitment to QbD (Quality-by-Design) and DFMA (Design for Manufacturing and Assembly) and by implementing shelf-life studies in the early phase of the development process, we minimize production costs and reduce overall risks for your product.

4. Development or transfer of QC methodologies

To ensure a constant high quality and reproducibility of the products, existing QC methods are implemented or new method developedWith joint assay calibrations at both sites, we ensure that verification of development output can immediately be used for design transfer and production. The analytical methods used by Applyo are listed in “Analytical QC and Product Development Support”.

5. Compilation of SOPs and other documents according to 21 CFR 820 and ISO 13485

Applyo issues the documentation of SOPs and all documents required according to 21 CFR 820 and ISO 13485 in a fully digitized way by using state-of-the-art LIMS, LES and QMS. These systems work together and provide full traceability – starting from incoming material over the execution of production to quality check and documentation of all materials and final products.

6. Validation and Verification

Applyo ensures full compliance with IVDR, DIN EN ISO 13485 and 21 CFR 820 by developing all products and processes according to the stated guidelines. Additionally we follow the QbD approach used in pharmaceutical industry.

7. Support for submissions to regulatory authorities.

With our expertise in development of IVD PoC devices we can address critical regulatory requirements in advance and safe unnecessary development loops. We provide our support at every stage of product development until submission to the regulatory authorities.

Do you …

… want to transform liquid reagents into ready-to-use beads?

… require single-portioned reactions easy to handle?

… search for a partner who provides you with high-quality and low-cost LyoBeads?

… look for handling and packaging tools or for concepts to integrate reactions into devices?

… have the need for upscaling your production volumes?

Applyo is your partner of choice when you require large batches of lyophilized reagents with high and homogenous quality. We service you with unit sizes from a few ml to several liters which correspond to quantities from 100 beads up to millions of beads per batch.

Time for transfer and adaptation from development or from existing freeze-drying protocols is minimized by Applyo’s analytical methods and through Applyo’s process validation & verification expertise.

1. Procurement and QC of (raw) materials

You can provide us with all or a selection of reagents required for your product or you can choose to use Applyo’s service for the procurement of the substances. We offer the complete supply chain services from supplier selection and evaluation to qualification. Benefit from our knowledge about reliable sources for materials.

2. Initiation of production flow in LIMS/LES

For Applyo production preparation means not only the physical preparation of the production workflow but also the complete tracing of the production in LIMS/LES. Hence, we can fully control our processes over the entire value chain with a systematic batch traceability.

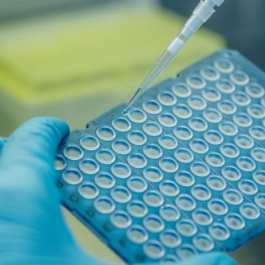

3. Mix preparation & dispensing

Mix preparation and dispensing at Applyo is a highly automated and monitored process. During production of the (sub)mixes for lyophilization our employees are guided through each single production step via LES. Dispensing is performed using automated pipetting robots for highest precision and accuracy.

4. Lyophilization

At our location in Jena, we provide an industrial manufacturing process for a stable freeze-drying production with significant upscaling possibilities and ecomonies of scale. Precise parameter control and a dedicated team with many years of practical experience ensure homogenous beads of the same high quality with every batch. read more

5. Quality control

Applyo utilizes validated and verified QC methods in line with your standards and routines. This facilitates your processes for incoming QC and generates a seamless consistency of batch deliveries and data provision. Synchronized assays ensure product quality compliance. Additionally, the use of modern LIMS, LES and QMS provides full traceability of each batch.

6. handling, packaging & labeling

Applyo offers the following packaging and labelling options:

Labelling can be performed at the level you require. Let us know your requirements and demands and we will propose suitable solutions for your requests.

7. Storage & shipping

Applyo offers customized storage and shipping conditions. For full traceability loggers can be used or initial validation of packaging and shipping according to ISTA 2Ad transport simulation can be realized – we provide suitable solutions according to your demands.We are experienced with IVDR PoC products intended for aWHO prequalification programm which must fulfill bTGS-1 to -8 series guidelines.

a https://www.who.int/rhem/prequalification/prequalification_of_medicines/en/

b https://apps.who.int/iris/discover?rpp=10&etal=0&query=tgs&group_by=none&page=1

The development of an effective QC strategy from raw materials over intermediate mixes to final reagents is a success factor for robust production. A sound understanding of the materials used and their impact on the product is essential to mitigate non-conforming products. As we are committed to the QbD approach we use a multiple set of analytical methods for characterization of raw-, intermediate- and final products:

And via our partner network we also provide:

We develop all products and processes according to guidelines as stated by IVDR, DIN EN ISO 13485 and 21 CFR 820, additionally considering the QbD approach used in pharmaceutical industry. Once validated the methods are regularly verified and can also be applied at our customers after reverification for e.g., incoming QC.

The experts of Applyo Jena developed many biochemical and molecular biology assays for diagnostic application but also for quality control.

Assays and methods used for QC or production are validated according to standardized ISO and ANSI guidelines as requested by CLSI or WHO TGS-1. With respect to assay development for PCR we follow CLSI MM17-Aa, ISO 5725 Series 1-6b and The MIQE Guidelinesc.

a https://clsi.org/standards/products/molecular-diagnostics/documents/mm17/

b https://www.iso.org/ics/17.020/x/

c https://doi.org/10.1373/clinchem.2008.112797

In fully integrated IVD-PoC or PoN products, all reagents required for performing a molecular PCR test are stored “on-board” in a consumable or cartridge. In particular, moisture sensitive freeze-dried reagents for PCR containing critical reagents such as enzymes (Taq DNA Polymerase, Reverse-Transcriptase, Ligases, Nucleases), dNTPs, primers and probes are stored adjacent to and must be protected from liquid buffer solutions. Therefore, the design of the consumable cartridge, the choice of materials (properties such as water vapor transmission rate (WVTR) and the production strategy (hot melt vs. laser and ultrasonic welding) must be considered. With a focus on DFMA and QbD as leading methodologies Applyo Jena supports you in developing a cost-effective IVD-PoC solution and in shortening the time-to-market for your product.

Applyo also supports you with automated pick-and-place solutions for packaging in standard consumables and dual chamber solutions as well as customized cartridge assembling. Please feel free to discuss your requirements with us.

Do you…

…like to develop a new assay,

…need to optimize an existing one or

…just want to transform your reagent mixture into a freeze-dried version?

Applyo supports you in assay-, formulation- and lyophilization development. With our services you can enhance your development possibilities, expand your capabilities and accelerate your time-to-market. Avoid numerous trial-and-error loops with our systematic approach.

Definition of Product and Material

↓

Design or Adaption of Reagent Mixtures

↓

Optimization of Reagent Mixes

↓

Development of QC Methods

↓

Compilation of Documents 21CFR 820 + ISO13485

↓

Validation and Verification

↓

Support for submissions to regular authorities

1. Definition of product and materials

Your product with its unique characteristics will be analyzed in detail with our experts before the design of the formulation starts. A common understanding of the desired properties is the basis for our streamlined development project.

In this analysis we also discuss boundaries such as production or transport conditions, while taking Regulatory Requirements (e.g. TGS-1 to -8 seriesa and ISTA 2Ab) into account.

Even after extreme and unlikely transport conditions our Applyo RMDx RT-qPCR beads will show optimal performance and shelf-life.

a https://apps.who.int/iris/discover?rpp=10&etal=0&query=tgs&group_by=none&page=1

b ISTA 2A standard defines conditions for transport simulation and is accepted by the FDA for Medical Device Packaging. https://ista.org/test_procedures.php#partial-simulation-section

2. Design or adaptation of formulation

Almost every master mix can be transferred to a freeze-dried version. However, adaptations are recommended or even mandatory to obtain a cost-effective and robust product with high quality. With Applyo’s experience in formulation development we can significantly improve your products performance, shelf-life and overall product costs.

3. Optimization of mixes with respect to shelf-life and robustness, performance, production costs (DFMA)

To achieve the best product performance with minimum optimization loops during product development, we approach projects with well thought development strategies. With our commitment to QbD (Quality-by-Design) and DFMA (Design for Manufacturing and Assembly) and by implementing shelf-life studies in the early phase of the development process, we minimize production costs and reduce overall risks for your product.

4. Development or transfer of QC methodologies

To ensure a constant high quality and reproducibility of the products, existing QC methods are implemented or new method developedWith joint assay calibrations at both sites, we ensure that verification of development output can immediately be used for design transfer and production. The analytical methods used by Applyo are listed in “Analytical QC and Product Development Support”.

5. Compilation of SOPs and other documents according to 21 CFR 820 and ISO 13485

Applyo issues the documentation of SOPs and all documents required according to 21 CFR 820 and ISO 13485 in a fully digitized way by using state-of-the-art LIMS, LES and QMS. These systems work together and provide full traceability – starting from incoming material over the execution of production to quality check and documentation of all materials and final products.

6. Validation and Verification

Applyo ensures full compliance with IVDR, DIN EN ISO 13485 and 21 CFR 820 by developing all products and processes according to the stated guidelines. Additionally we follow the QbD approach used in pharmaceutical industry.

7. Support for submissions to regulatory authorities.

With our expertise in development of IVD PoC devices we can address critical regulatory requirements in advance and safe unnecessary development loops. We provide our support at every stage of product development until submission to the regulatory authorities.

Do you …

… want to transform liquid reagents into ready-to-use beads?

… require single-portioned reactions easy to handle?

… search for a partner who provides you with high-quality and low-cost LyoBeads?

… look for handling and packaging tools or for concepts to integrate reactions into devices?

… have the need for upscaling your production volumes?

Applyo is your partner of choice when you require large batches of lyophilized reagents with high and homogenous quality. We service you with unit sizes from a few ml to several liters which correspond to quantities from 100 beads up to millions of beads per batch.

Time for transfer and adaptation from development or from existing freeze-drying protocols is minimized by Applyo’s analytical methods and through Applyo’s process validation & verification expertise.

1. Procurement and QC of (raw) materials

You can provide us with all or a selection of reagents required for your product or you can choose to use Applyo’s service for the procurement of the substances. We offer the complete supply chain services from supplier selection and evaluation to qualification. Benefit from our knowledge about reliable sources for materials.

2. Initiation of production flow in LIMS/LES

For Applyo production preparation means not only the physical preparation of the production workflow but also the complete tracing of the production in LIMS/LES. Hence, we can fully control our processes over the entire value chain with a systematic batch traceability.

3. Mix preparation & dispensing

Mix preparation and dispensing at Applyo is a highly automated and monitored process. During production of the (sub)mixes for lyophilization our employees are guided through each single production step via LES. Dispensing is performed using automated pipetting robots for highest precision and accuracy.

4. Lyophilization

At our location in Jena, we provide an industrial manufacturing process for a stable freeze-drying production with significant upscaling possibilities and ecomonies of scale. Precise parameter control and a dedicated team with many years of practical experience ensure homogenous beads of the same high quality with every batch. read more

5. Quality control

Applyo utilizes validated and verified QC methods in line with your standards and routines. This facilitates your processes for incoming QC and generates a seamless consistency of batch deliveries and data provision. Synchronized assays ensure product quality compliance. Additionally, the use of modern LIMS, LES and QMS provides full traceability of each batch.

6. handling, packaging & labeling

Applyo offers the following packaging and labelling options:

Labelling can be performed at the level you require. Let us know your requirements and demands and we will propose suitable solutions for your requests.

7. Storage & shipping

Applyo offers customized storage and shipping conditions. For full traceability loggers can be used or initial validation of packaging and shipping according to ISTA 2Ad transport simulation can be realized – we provide suitable solutions according to your demands.We are experienced with IVDR PoC products intended for aWHO prequalification programm which must fulfill bTGS-1 to -8 series guidelines.

a https://www.who.int/rhem/prequalification/prequalification_of_medicines/en/

b https://apps.who.int/iris/discover?rpp=10&etal=0&query=tgs&group_by=none&page=1

The development of an effective QC strategy from raw materials over intermediate mixes to final reagents is a success factor for robust production. A sound understanding of the materials used and their impact on the product is essential to mitigate non-conforming products. As we are committed to the QbD approach we use a multiple set of analytical methods for characterization of raw-, intermediate- and final products:

And via our partner network we also provide:

We develop all products and processes according to guidelines as stated by IVDR, DIN EN ISO 13485 and 21 CFR 820, additionally considering the QbD approach used in pharmaceutical industry. Once validated the methods are regularly verified and can also be applied at our customers after reverification for e.g., incoming QC.

The experts of Applyo Jena developed many biochemical and molecular biology assays for diagnostic application but also for quality control.

Assays and methods used for QC or production are validated according to standardized ISO and ANSI guidelines as requested by CLSI or WHO TGS-1. With respect to assay development for PCR we follow CLSI MM17-Aa, ISO 5725 Series 1-6b and The MIQE Guidelinesc.

a https://clsi.org/standards/products/molecular-diagnostics/documents/mm17/

b https://www.iso.org/ics/17.020/x/

c https://doi.org/10.1373/clinchem.2008.112797

In fully integrated IVD-PoC or PoN products, all reagents required for performing a molecular PCR test are stored “on-board” in a consumable or cartridge. In particular, moisture sensitive freeze-dried reagents for PCR containing critical reagents such as enzymes (Taq DNA Polymerase, Reverse-Transcriptase, Ligases, Nucleases), dNTPs, primers and probes are stored adjacent to and must be protected from liquid buffer solutions. Therefore, the design of the consumable cartridge, the choice of materials (properties such as water vapor transmission rate (WVTR) and the production strategy (hot melt vs. laser and ultrasonic welding) must be considered. With a focus on DFMA and QbD as leading methodologies Applyo Jena supports you in developing a cost-effective IVD-PoC solution and in shortening the time-to-market for your product.

Applyo also supports you with automated pick-and-place solutions for packaging in standard consumables and dual chamber solutions as well as customized cartridge assembling. Please feel free to discuss your requirements with us.

Applyo Jena GmbH

Göschwitzer Straße 22

07745 Jena

Deutschland

Phone: +49 (0)3641 554 788-0

Fax: +49 (0)3641 554 788-1

E-Mail: info@applyo-jena.com

Web: www.applyo-jena.com

Manufacturer of molecular biology reagent mixtures for research and development laboratories, as well as reagent and diagnostics manufacturers – stable at room temperature and suitable for immediate use.

Applyo Jena GmbH

Göschwitzer Straße 22

07745 Jena

Deutschland

Phone: +49 (0)3641 554 788-0

Fax: +49 (0)3641 554 788-1

E-Mail: info@applyo-jena.com

Web: www.applyo-jena.com

Manufacturer of molecular biology reagent mixtures for research and development laboratories, as well as reagent and diagnostics manufacturers – stable at room temperature and suitable for immediate use.

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.