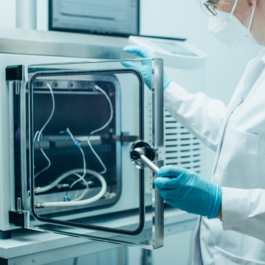

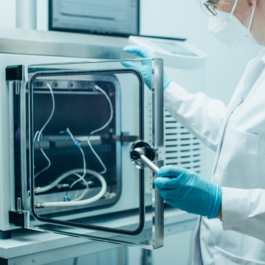

GMP Compliance – Adhering to Good Manufacturing Practices (GMP) with aseptic processing and only pharmaceutical grade materials

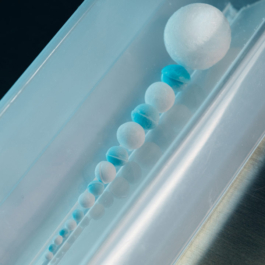

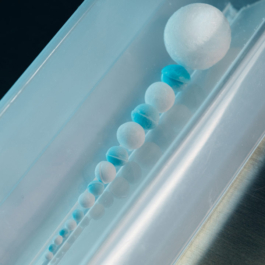

Highly precise bead size – beads are produced using high end dosing technology – with a broad size range from 1.6 mm to > 8 mm diameter (2 µL to > 250 µL

High Homogeneity – Uniform size and weight for accurate dosing and controlled delivery of active ingredients in a range of approx. 2 % CV.

Highly scalable Process – Facilitating large-scale production while preserving quality and consistency.

Broad Compatibility – Suitable for injectables, inhalables, eye drops, oral dosing, pipet dosing after dissolving in water, and other advanced delivery systems.

Superior Stability – Protects active ingredients, maintaining their potency and extending shelf life.

Cost Efficiency – Lower production costs through efficient manufacturing while their uniform shape ensures ease of sterile transport, reducing logistical expenses.

Together with our investors, we are actively seeking partnerships to bring Lyo-Bead technology to the forefront of the pharmaceutical industry. If you’re interested in pioneering this innovative solution, we invite you to collaborate with us.

Join us today to lead the way in pharmaceutical innovation.

Contact us now to explore how Lyo-Beads can transform your business!

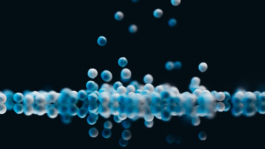

Lyo-Beads with our patented process offer a unique and practical alternative to traditional lyophilized forms like cakes, powders, and particles. These spherical beads are produced by freezing individual droplets before lyophilization, resulting in:

a. Ease of Use for Patients and Providers

b. Precision in Dosing and Consistency

c. Efficiency in Production and Packaging

d. Enhanced Reconstitution Properties

Lyo-Beads are highly adaptable to diverse pharmaceutical needs:

The flexibility of Lyo-Beads lies in their ability to meet diverse formulation and application needs while delivering unmatched consistency, stability, and scalability. While currently tailored for reagents, further development could expand their applicability into pharmaceutical markets. By streamlining production processes, enhancing drug delivery, and simplifying use, Lyo-Beads emerge as a transformative innovation in modern pharmaceutical and biotechnological applications.

Are you ready to explore the possibilities? Join us in leveraging the power of Lyo-Beads to redefine the pharmaceutical landscape for both human and animal health.

GMP Compliance – Adhering to Good Manufacturing Practices (GMP) with aseptic processing and only pharmaceutical grade materials

Highly precise bead size – beads are produced using high end dosing technology – with a broad size range from 1.6 mm to > 8 mm diameter (2 µL to > 250 µL

High Homogeneity – Uniform size and weight for accurate dosing and controlled delivery of active ingredients in a range of approx. 2 % CV.

Highly scalable Process – Facilitating large-scale production while preserving quality and consistency.

Broad Compatibility – Suitable for injectables, inhalables, eye drops, oral dosing, pipet dosing after dissolving in water, and other advanced delivery systems.

Superior Stability – Protects active ingredients, maintaining their potency and extending shelf life.

Cost Efficiency – Lower production costs through efficient manufacturing while their uniform shape ensures ease of sterile transport, reducing logistical expenses.

Together with our investors, we are actively seeking partnerships to bring Lyo-Bead technology to the forefront of the pharmaceutical industry. If you’re interested in pioneering this innovative solution, we invite you to collaborate with us.

Join us today to lead the way in pharmaceutical innovation.

Contact us now to explore how Lyo-Beads can transform your business!

Lyo-Beads with our patented process offer a unique and practical alternative to traditional lyophilized forms like cakes, powders, and particles. These spherical beads are produced by freezing individual droplets before lyophilization, resulting in:

a. Ease of Use for Patients and Providers

b. Precision in Dosing and Consistency

c. Efficiency in Production and Packaging

d. Enhanced Reconstitution Properties

Lyo-Beads are highly adaptable to diverse pharmaceutical needs:

The flexibility of Lyo-Beads lies in their ability to meet diverse formulation and application needs while delivering unmatched consistency, stability, and scalability. While currently tailored for reagents, further development could expand their applicability into pharmaceutical markets. By streamlining production processes, enhancing drug delivery, and simplifying use, Lyo-Beads emerge as a transformative innovation in modern pharmaceutical and biotechnological applications.

Are you ready to explore the possibilities? Join us in leveraging the power of Lyo-Beads to redefine the pharmaceutical landscape for both human and animal health.

Applyo Jena GmbH

Göschwitzer Straße 22

07745 Jena

Deutschland

Phone: +49 (0)3641 554 788-0

Fax: +49 (0)3641 554 788-1

E-Mail: info@applyo-jena.com

Web: www.applyo-jena.com

Manufacturer of molecular biology reagent mixtures for research and development laboratories, as well as reagent and diagnostics manufacturers – stable at room temperature and suitable for immediate use.

Applyo Jena GmbH

Göschwitzer Straße 22

07745 Jena

Deutschland

Phone: +49 (0)3641 554 788-0

Fax: +49 (0)3641 554 788-1

E-Mail: info@applyo-jena.com

Web: www.applyo-jena.com

Manufacturer of molecular biology reagent mixtures for research and development laboratories, as well as reagent and diagnostics manufacturers – stable at room temperature and suitable for immediate use.

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.